Once Gerard was finished, not much more instruction was needed by John before everyone had an idea of how to apply Gerard's abstract ideas to a practical pipe frame.

Even though the easy way to cut the pipes for a frame is with a metal chop saw, not everyone has one or can afford to buy one. We used hacksaws, which are relatively cheap at hardware stores or even Wally World.

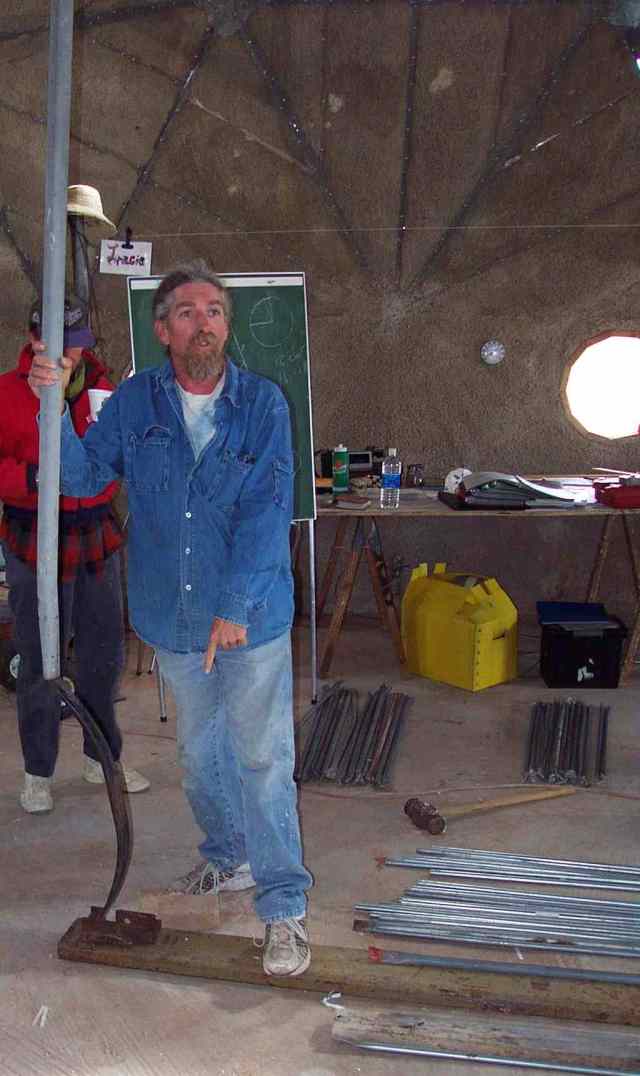

The ends of the pipes can be crushed with a hammer, and we did one that way to see how, but we did it the easy way instead. John demonstrated a pipe crusher that was made from junk car parts and can crush the end of a pipe with two strokes.

This made fast work of preparing the pipes for drilling.

The dome stick was attached to a drill press, and the jig pins were used for precision measurement between the holes. A hand drill was used at the same time to drill pipes, and it was observed that the hand drill was about as fast as the drill press, though not quite as accurate.

Everyone got their fill of cutting, crushing, and drilling long before enough pipes were made for the complete 5/9 dome, and everyone was very familiar with the procedure. We adjourned outside to assemble a partial frame.

To save time, we put together 3/9 of a sphere, enough to learn what was needed. To complete the 5/9 sphere more pipes in the same pattern would be added.

The frame was easily flipped by a few people, and we stopped to eat.

Lunch for the second day was vegetarian again, enchiladas and tamales with lentils and rice on the side.